|

|

|

MSF/PSF-3M

Position Sensitive Detector X-ray Stress Analyzer

|

The PSPC (Position Sensitive Proportional Counter) may be said to be a linear counter as opposed to the SC and PC which are point counters. While the latter counters obtain diffracted X-rays by scanning over the given angular range for measurement, the former counter performs simultaneous counting over a section of 50 to 100 mm in the longitudinal direction i.e.; approximately 20° in 2θ range. The PSPC has excellent resolving power. Simultaneous counting of a 20 degree range, with no need of detector scanning, has substantially reduced the measurement time. Thus allowing rapid measurement. Moreover, the capability of integrated measurement permits detection of exceedingly weak diffracted X-rays from micro areas. Rigaku has incorporated this PSPC detector with its X-ray stress analyzer system to obtain high-speed and micro-area measurement of residual stress.

|

|

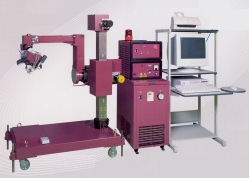

Rapid Type X-ray Stress Analyzer:

PSPC/MSF

Permits high-speed measurement. Compared with the conventional method, the measurement time can be reduced drastically, 10 to 100 times faster depending upon the kind of measurement. This is a field oriented X-ray stress analyzer that enables the operator to immediately get stress values from a simple operation.

-

Data on the stress value is immediately

available.

-

Optimal system for field operation - allows bulk

processing of samples to be measured.

-

Can analyze any sample shape.

-

lncorporates various measurement methods

such as the iso-inclination method,

side-inclination method, etc.

|

Strainflex MSF-3M

Strainflex PSF-3M

|

|

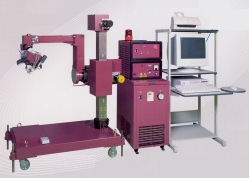

Micro Area X-ray Stress Analyzer:

PSPC/MICRO STRESS

The PSPC and a special optical system jointly get precise information on residual stress existing in micro areas as small as 0.15 mm in diameter. Up to now, detection from such extremely small areas has been considered difficult. As such, this system is most suitable for samples with complex features and very small grain size measurements (e.g., carbonized steel, ceramics, etc.)

|

Micro Area type

|

-

Residual stress measurement, of micro areas of 0.15 mm diameter and above,

in a short time.

-

The system allows immediate data processing upon completion of measurement.

-

Perfect optimal system for measurement of residual stress in IC packages -

especially those components that have undergone ultraprecision machining

or fabrication shaping.

-

X-ray beam size is selectable between 0.15 mm and 2 mm diameter - by using the

appropriate incident collimator.

-

Incorporates various measurement methods such as the iso-inclination method,

side-inclination method, etc.

-

Optional motor-driven X-Y stage.

|

|

|

|

|

|

|